1. System Overview

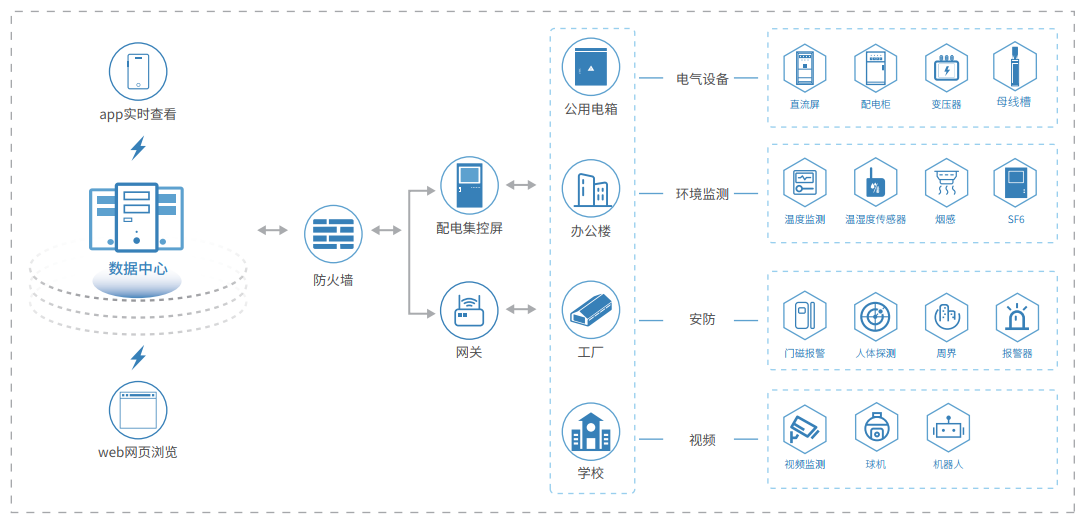

The Hangyue Intelligent Operation and Maintenance Management System is an intelligent service platform centered on "Intelligent Distribution Operation and Maintenance Services," integrating functions such as data collection, transmission, analysis, monitoring, protection, early warning, and management. The system transmits operational data of electrical equipment on both supply and demand sides in real-time to the cloud platform via IoT sensing terminals (field monitoring modules, transmission modules) for unified management, achieving multi-dimensional interconnection from the field to the cloud, and from the cloud to APP and Web. It employs technologies such as Internet + IoT, cloud computing, big data analysis, and artificial intelligence to realize multi-dimensional intelligent learning, analysis, identification, early warning, feedback control, and maintenance management of equipment health. This makes electrical safety supervision simpler, energy use more efficient, and energy-saving measures more precise, thereby eliminating potential safety hazards, improving energy efficiency, and achieving precise energy saving. It realizes multi-dimensional equipment and system management goals of "safe, reliable, economical, and intelligent."

2. System Features

AI Equipment Prediction

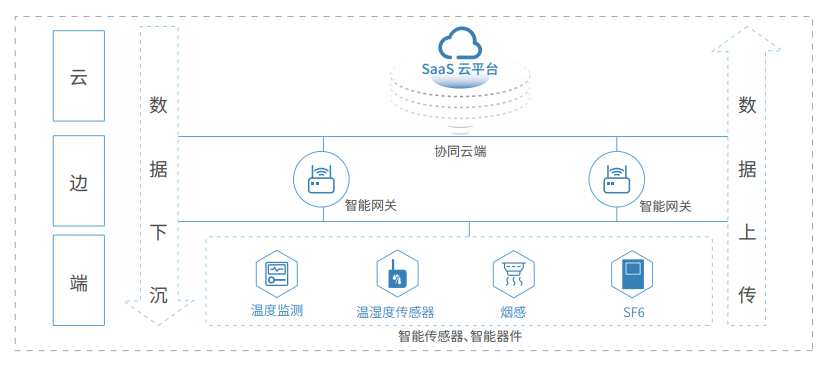

AI equipment prediction includes equipment health prediction and equipment load prediction; the system cloud captures massive data generated by the operation of distribution equipment and uses AI algorithms, through machine learning and deep learning, to generate online prediction models. These models are deployed to edge intelligent gateways, where combined with real-time operating data, they perform real-time analysis and early warning of equipment health. The predictions guide offline maintenance work, shifting from a passive maintenance mode of reactive repairs to a proactive maintenance mode of predictive inspections, effectively avoiding property loss and personal harm caused by power equipment failures.

Equipment Full Lifecycle Management

The system integrates big data technology, internet technology, IoT technology, cloud computing, edge computing, and artificial intelligence to provide advanced full lifecycle equipment management, including static asset attributes and measurement point attributes, dynamic real-time operation records such as current, voltage, temperature, humidity, partial discharge, leakage current, harmonics, number of switch operations, trip counts, segmented current, cumulative leakage current, maintenance records, over-temperature occurrences, overload occurrences, alarm records, and maintenance records.

Support for Operation and Maintenance Drawing Management

Distribution equipment drawings are an important part of the equipment and play a crucial role in operation and maintenance; equipment drawings include static schematics, wiring diagrams, and dynamic real-time monitoring diagrams and trend analysis charts. These drawings can be pushed through the system to offline maintenance personnel's mobile phones to support and guide offline maintenance.

Equipment Asset Management

Distribution equipment is an important asset of enterprises, including transformers, bus ducts, distribution cabinets, distribution boxes, etc. The system has established a rich measurement point code library and equipment model library, widely supporting various equipment access to the system. After importing the equipment list via Excel, it becomes enterprise assets. The system automatically pulls required measurement point information from the equipment model library and measurement point code library, automatically generates point tables, and issues them to edge gateways to achieve data collection. Using Hangyue digital graphic technology, it automatically generates high and low voltage primary wiring diagrams and distribution box wiring topology diagrams, realizing automated construction of online graphic monitoring. Any wiring changes or equipment attribute updates will automatically synchronize the online monitoring diagrams, achieving efficient management of equipment assets.

3. Customer Value

Promote Operation and Maintenance Mode Transformation and Innovation

Intelligent control of energy-consuming equipment such as water, electricity, and gas ensures equipment operates in the optimal energy-saving state, greatly reducing unnecessary energy waste.

Promote the "Data + Operation and Maintenance = Customized Service" Model

For factories and buildings' medium and low voltage distribution rooms, power sales service companies, and engineering operation and maintenance companies, using big data, AI artificial intelligence, and intelligent assisted operation and maintenance technologies, new service content such as improvement suggestions for customers' distribution rooms is proposed to create exclusive services and enhance customer electricity usage experience.

Promote the Shift to Proactive Value-Added Service Model

Integrate resources and cooperate with professional teams to help customers optimize energy use structure and reduce energy costs by adopting an overall energy management operation model; assist customers in optimizing equipment maintenance processes, improving maintenance efficiency, and reducing maintenance costs by adopting a service + spare parts overall management operation model; promote "one-stop service" for operation and maintenance to achieve service model transformation.