1. System Overview

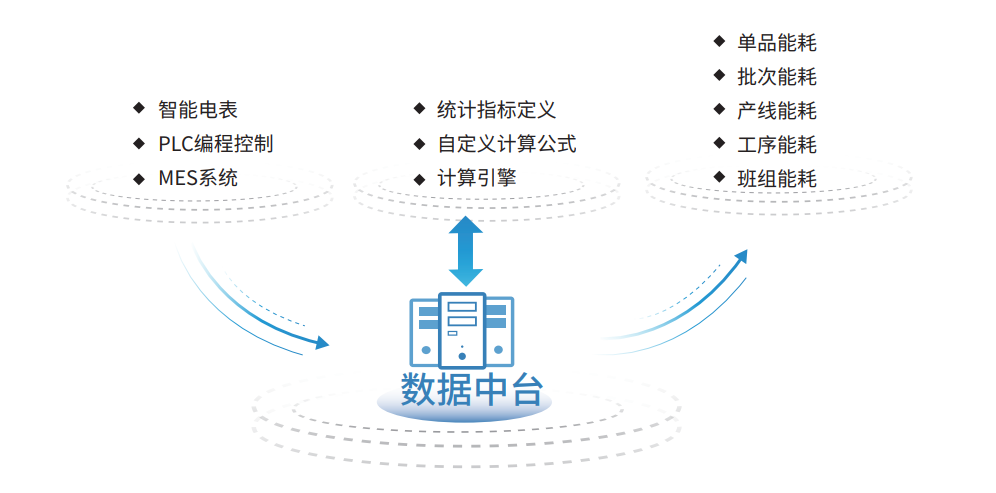

The factory energy consumption system focuses on energy saving and consumption reduction for high energy-consuming enterprises. It collects real-time data on the use of water, electricity, and gas by industrial production equipment, integrates production data from various production lines, and automatically calculates various energy consumption data, including: single product energy consumption, batch energy consumption, process energy consumption, production line single product energy consumption, production line energy consumption, workshop energy consumption, and team energy consumption. This provides reference information for enterprise managers to help them accurately understand the enterprise's energy consumption and unit consumption, thereby effectively implementing energy-saving management and transformation measures. By improving equipment efficiency and utilization, it reduces equipment energy consumption while meeting production demands.

2. System Functions

Single Product Energy Consumption Monitoring

Focuses on single product energy consumption by calculating, monitoring, and analyzing the energy consumption of each product to help users understand the energy consumption of each product.

Energy Consumption Comparison

Compares and analyzes energy consumption data of different products, production lines, or processes to help users identify products or stages with high energy consumption and take corresponding measures for energy-saving optimization.

Energy Consumption Prediction

Based on historical data and trend prediction models, forecasts future energy consumption to assist users in making reasonable energy planning and management decisions.

Energy Consumption Alarm

Sets warning rules for abnormal energy consumption. Once an abnormality is detected, the system automatically generates alarm information and promptly notifies relevant personnel to help users address issues in a timely manner.

Production Line Utilization Rate

Improves energy and equipment utilization by analyzing the production line utilization rate.

Energy Reports

Using the system's reporting tools combined with on-site collected data and statistical platform indicators, personalized reports can be customized as needed.

Production Line Energy Consumption

Calculates the energy consumption of each production line to provide a basis for equipment maintenance decisions based on energy, offering strong support for safe production.

Equipment Health

Utilizes artificial intelligence to learn the operating conditions of key energy-consuming equipment, enabling prediction and early warning of key equipment operation to avoid equipment failures.

|

|

3. Customer Value

Cost Control

By monitoring and analyzing single product energy consumption, factories can more accurately grasp the energy cost of each product, helping enterprises formulate reasonable cost control strategies, reduce production costs, and increase profit margins.

Energy Saving and Emission Reduction

By monitoring and managing single product energy consumption, factories can identify products or stages with high energy consumption, implement corresponding energy-saving measures, reduce energy consumption, lower carbon emissions, achieve green production, and enhance corporate social responsibility and sustainable development capabilities.

Product Quality Optimization

By monitoring single product energy consumption, factories can identify energy factors affecting product quality, promptly adjust production processes and parameters, improve product quality and production efficiency, and enhance market competitiveness.

Production Efficiency Improvement

By monitoring and analyzing single product energy consumption data, factories can identify bottlenecks and issues in the production process, optimize production workflows, improve production efficiency and capacity utilization, and reduce energy costs.

Data-Driven Decision Support

The factory energy consumption management system provides a large amount of real-time data and report analysis to help enterprise management make data-based decisions, optimize energy use and production planning, and improve management efficiency.

Safe Production

Using artificial intelligence technology for key equipment health management, it enables prediction, early warning, and forecasting of key equipment operation conditions to prevent equipment damage, production stoppages, personal injuries, and other accidents, ensuring safe production.